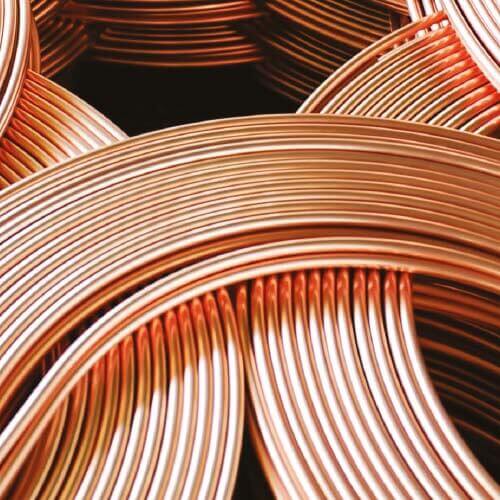

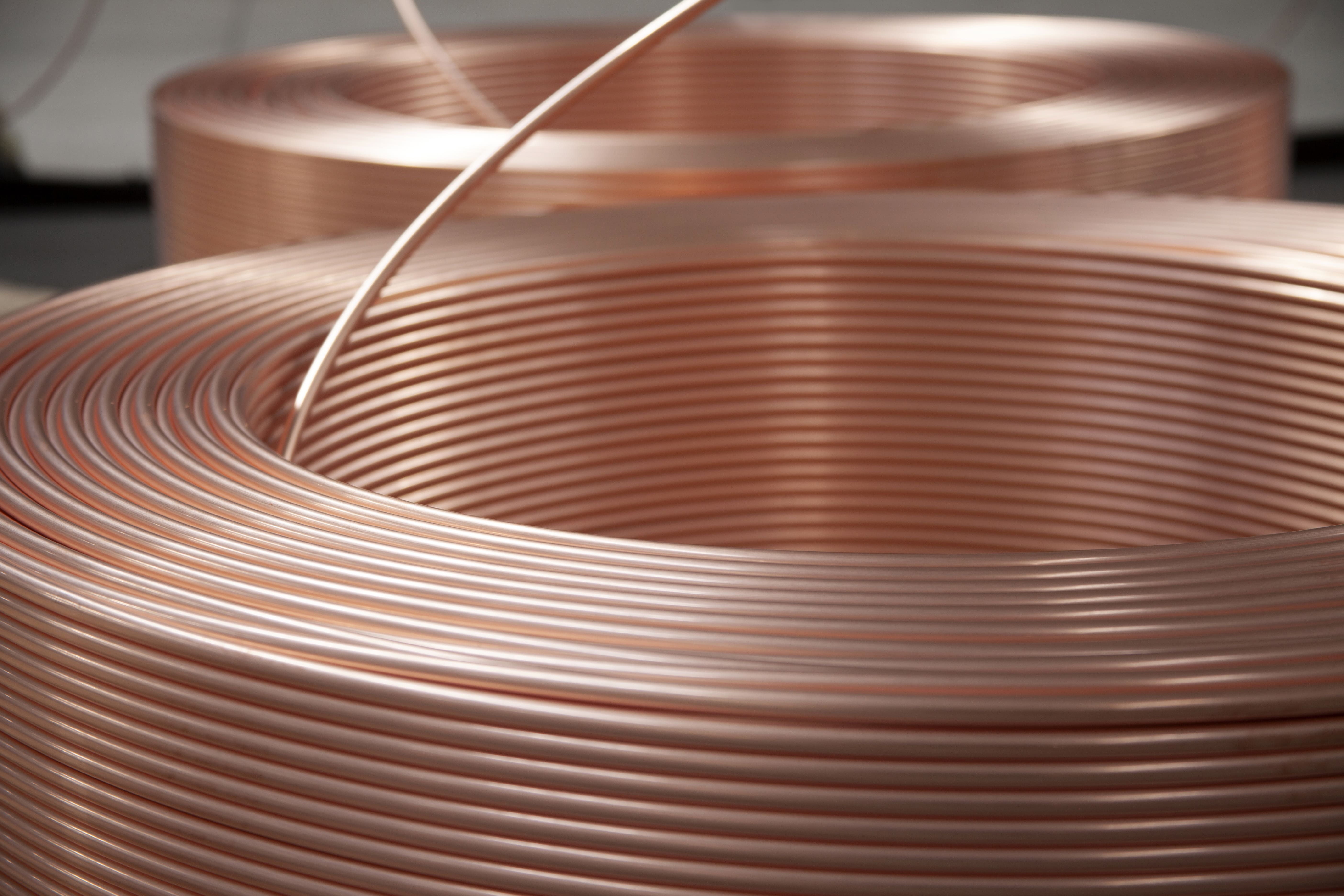

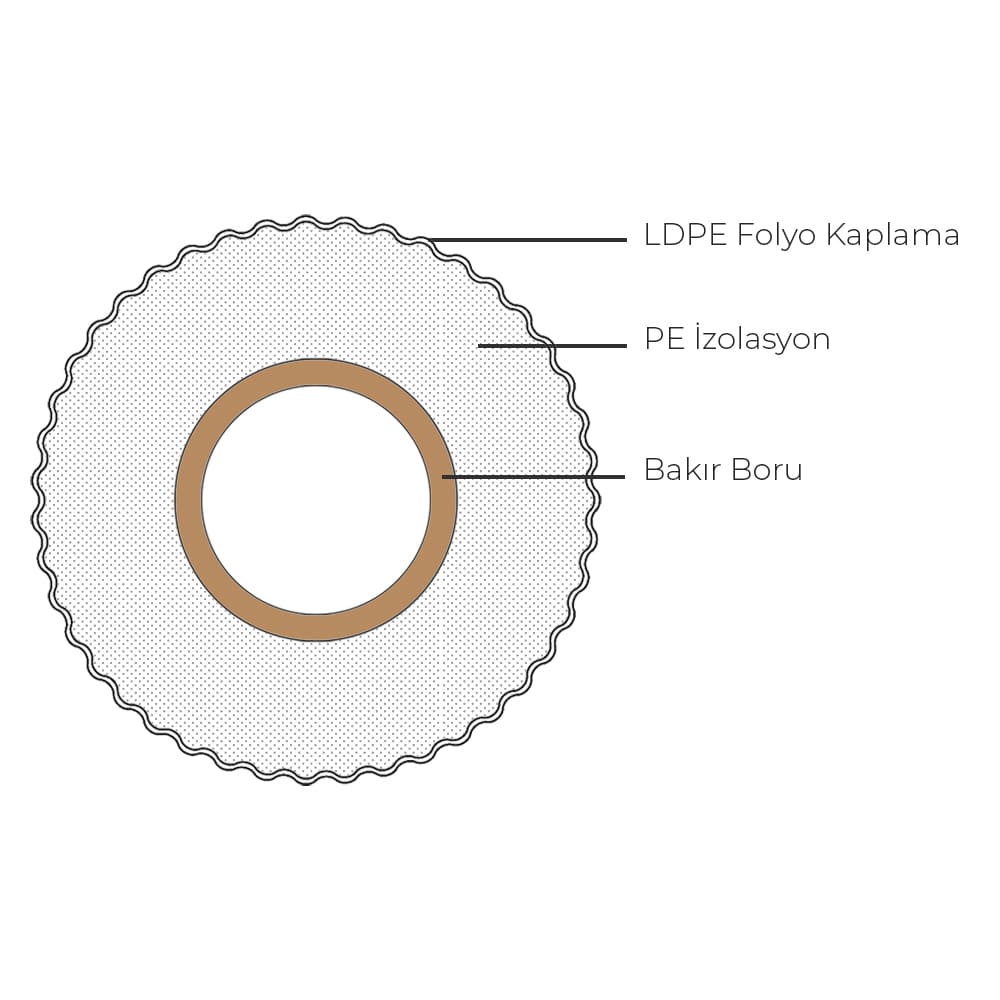

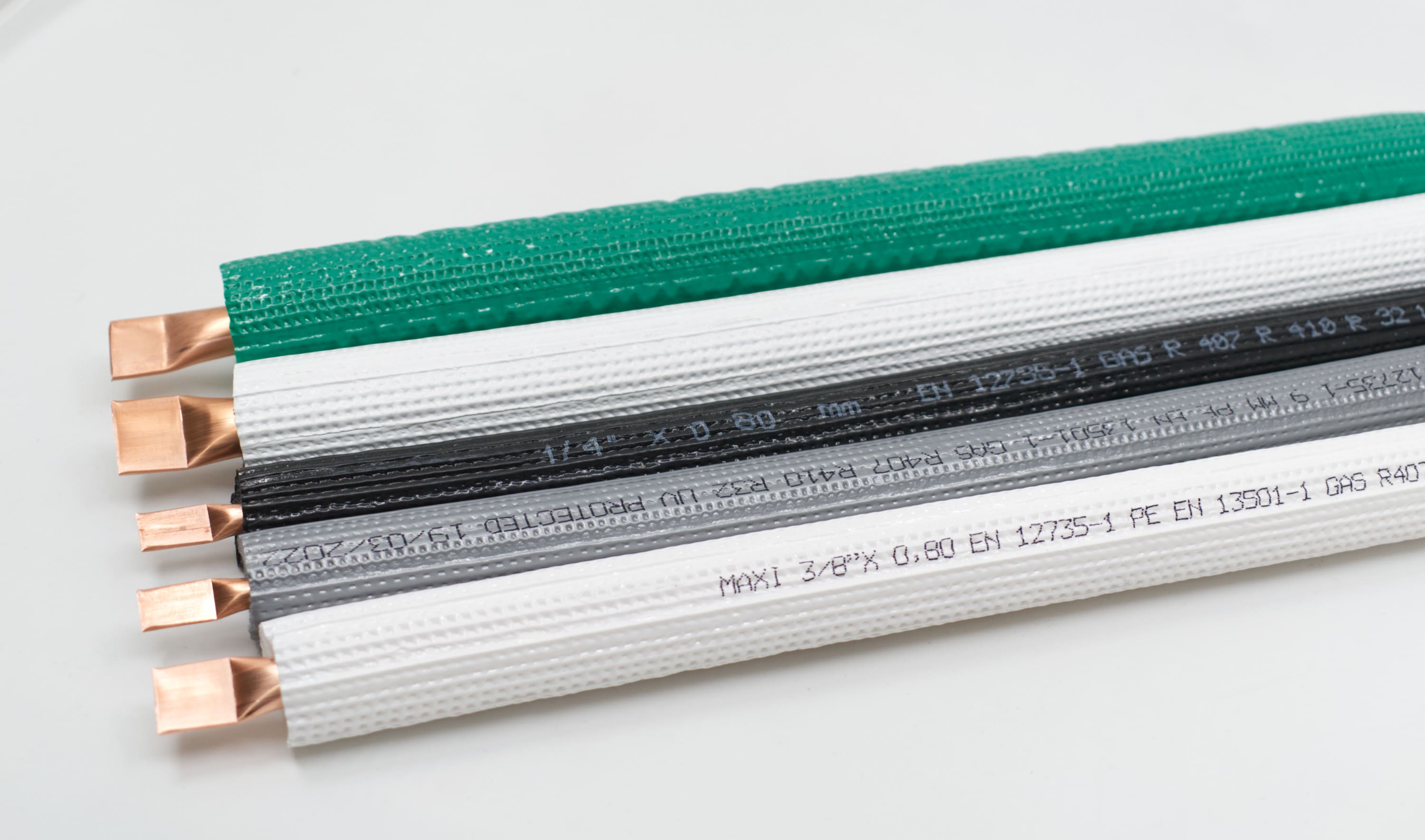

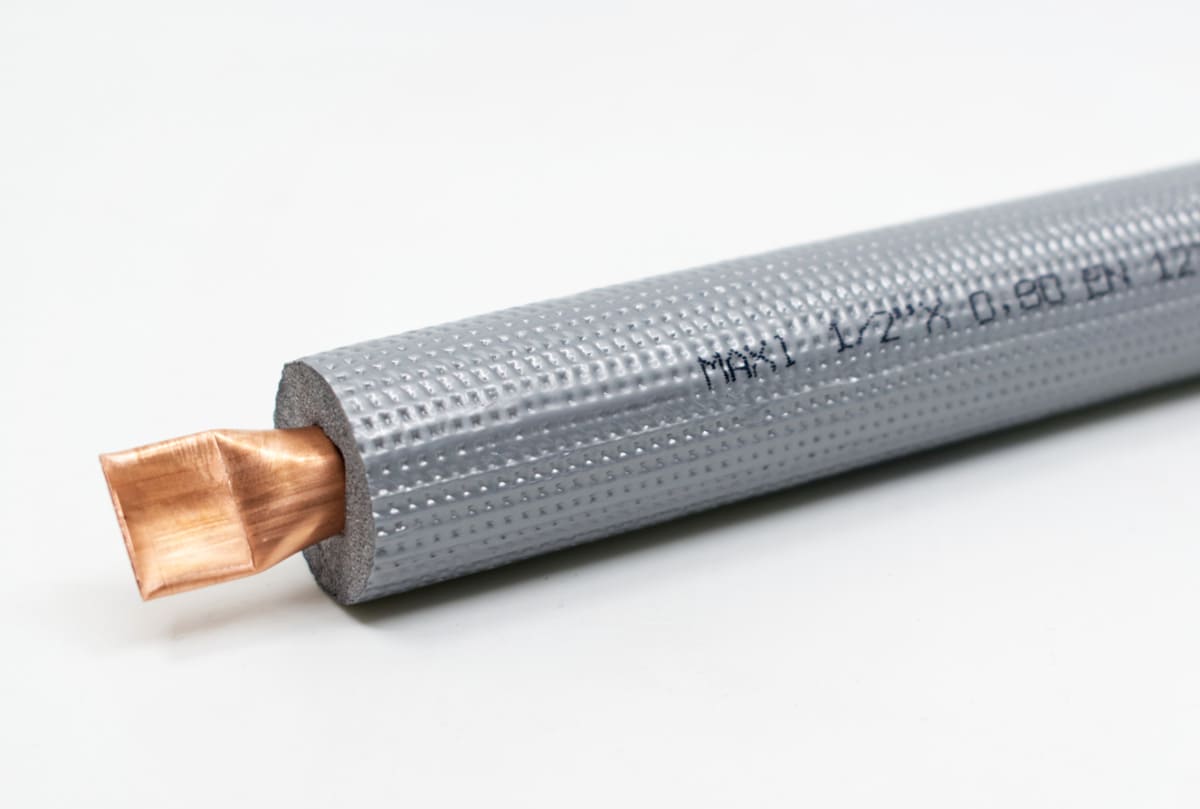

PE Insulated Copper Tube

PE Insulated Copper Pipe (Cu – Dhp 99.9%), specially designed for Split and VRV systems, completely insulates and protects the copper pipe thanks to its closed cell structure and LDPE foil coated surface. It draws attention with its fire extinguishing properties in accordance with DIN 4102-B1, SB1 BL S1D0 standards by providing superior safety against fire. Its (H) CFC-free environmentally friendly structure also provides high resistance to UV rays and external chemical effects, providing a long-lasting performance.

Technical Description

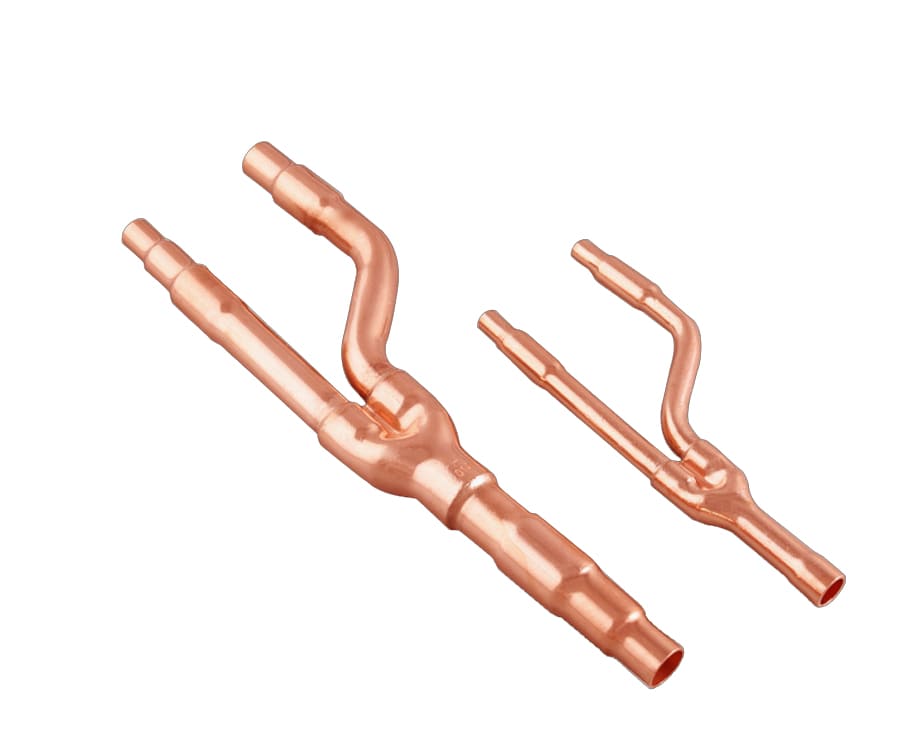

| PE-INSULATED COPPER TUBE PRODUCT CATEGORIES | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Diameter (inch) | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 7/8 | |

| SPLIT | 0.7 mm | 0.7 mm | 0.7 mm | 0.8 mm | |||

| POLAR | 0.75 mm | 0.75 | 0.75 mm | 0.9 mm | 0.9 mm | ||

| MAXI | 0.8 mm | 0.8 mm | 0.8 mm | 1.0 mm | 1.0 mm | 1.12 mm | |

| PLUS | 1.0 mm | 1.0 mm | 1.0mm | 1.0 mm | 1.0 mm | 1.12 mm | |

| White PE Insulated Copper Tube | |||||||

|---|---|---|---|---|---|---|---|

| Sustainability |

Fully recyclable |

||||||

| Specificities |

Unique aesthetical appearance

Excellent mechanical strength |

||||||

| Fire |

Excellent flame extingushing properties

SBI BL S1 DO |

||||||

| Health |

Produced without (H) CFC Complies to REACH Complies to VOC (Volatile organic componental ) Complies to RoHS (Restriction of Hazardous Substances) |

||||||

| Certificates |

Complies to the German EnEV

CE system 3 certified |

||||||

| Service temperatures |

Wide service temperature range

Minimum -80 °C Maksimum 95 °C (EN 14707) |

||||||

| Additional information |

Standart Thickness: 6,9,13,19 |

||||||

| Water |

Closed cell structure for good water vapor

barrier

Water vapor resistance μ ≥ 5000 (EN13469) Water absorption WS05 (EN 13472) |

||||||

| Insulation |

Semi-flexible thermoplastic foam

Excellent insulation properties

Lambda 0.040 W/mK at 40 °C

(EN ISO 8497)

Lambda 0.036 W/mK at 0 °C

(EN ISO 8497) |

||||||

| White PE Insulated Copper Tube | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Diameter (inch) |

1/4 | 3/8 | 1/2 | 1/2 | 5/8 | 3/4 | 7/8 |

| Pipe Thickness (mm) |

0,8 | 0,8 | 0,8 | 0,9 | 1 | 1 | 1,12 |

| Insulation Thickness (mm) |

6-9-13-19 | 6-9-13-19 | 6-9-13-19 | 6-9-13-19 | 6-9-13-19 | 6-9-13-19 | 6-9-13-19 |

| Operation Pressure (bar) |

134 | 89 | 72 | 84 | 62 | 52 | 42 |

| Coil Length (meter) |

15/50 | 15/50 | 15/50 | 15/50 | 15/50 | 15/50 | 15/50 |

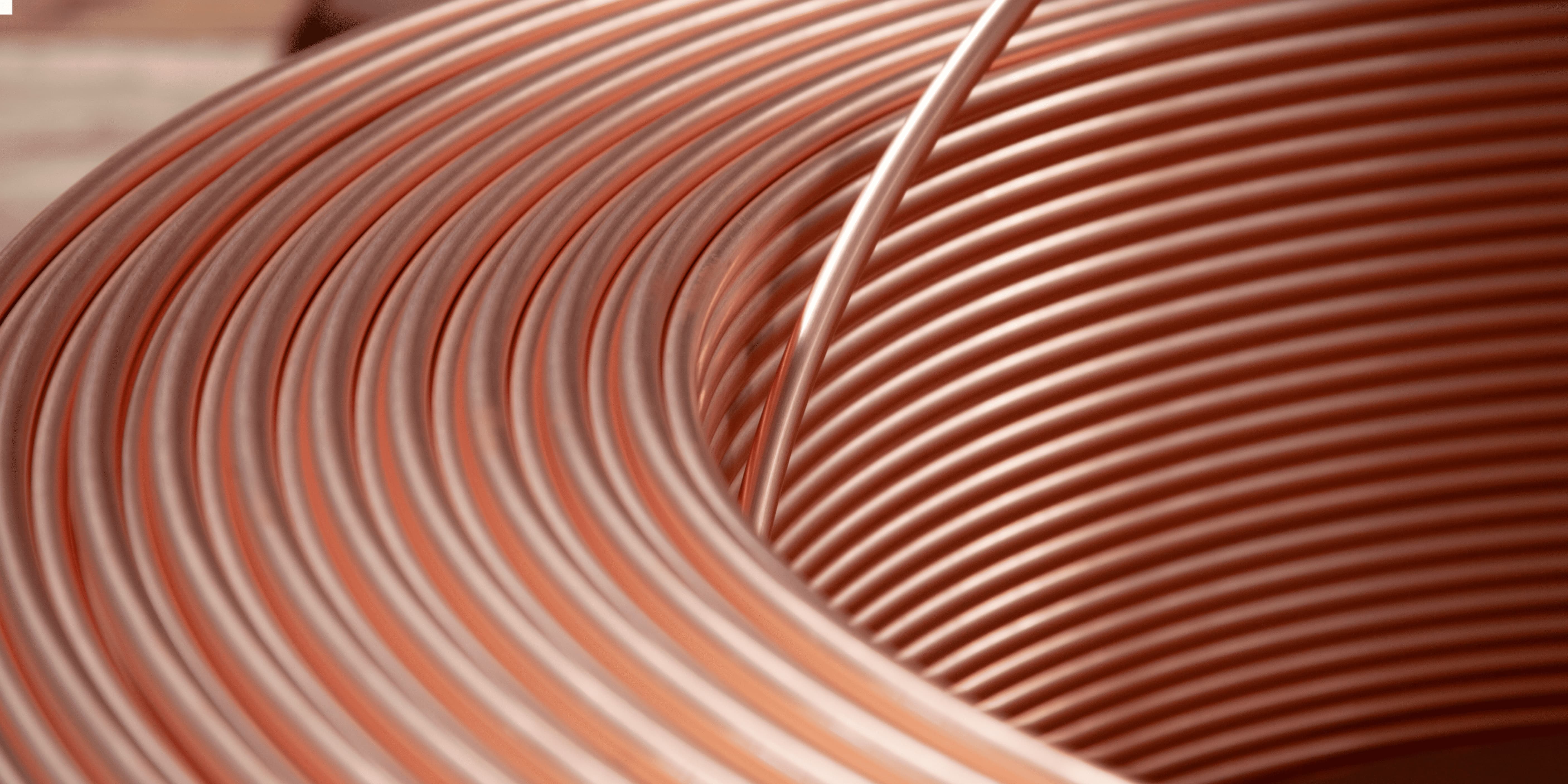

| TECHNICAL SPECS OF COPPER PIPE |

|||||||

|---|---|---|---|---|---|---|---|

| Chemical Composition |

99,9% Cu-Dhp | ||||||

| Conformity |

EN 12735 – 1 | ||||||

| Unit Breaking Load |

Min. R=220n/mm2 | ||||||

| Elongation A% |

A% min=45% | ||||||

| Physical Condition |

Annealed |

||||||

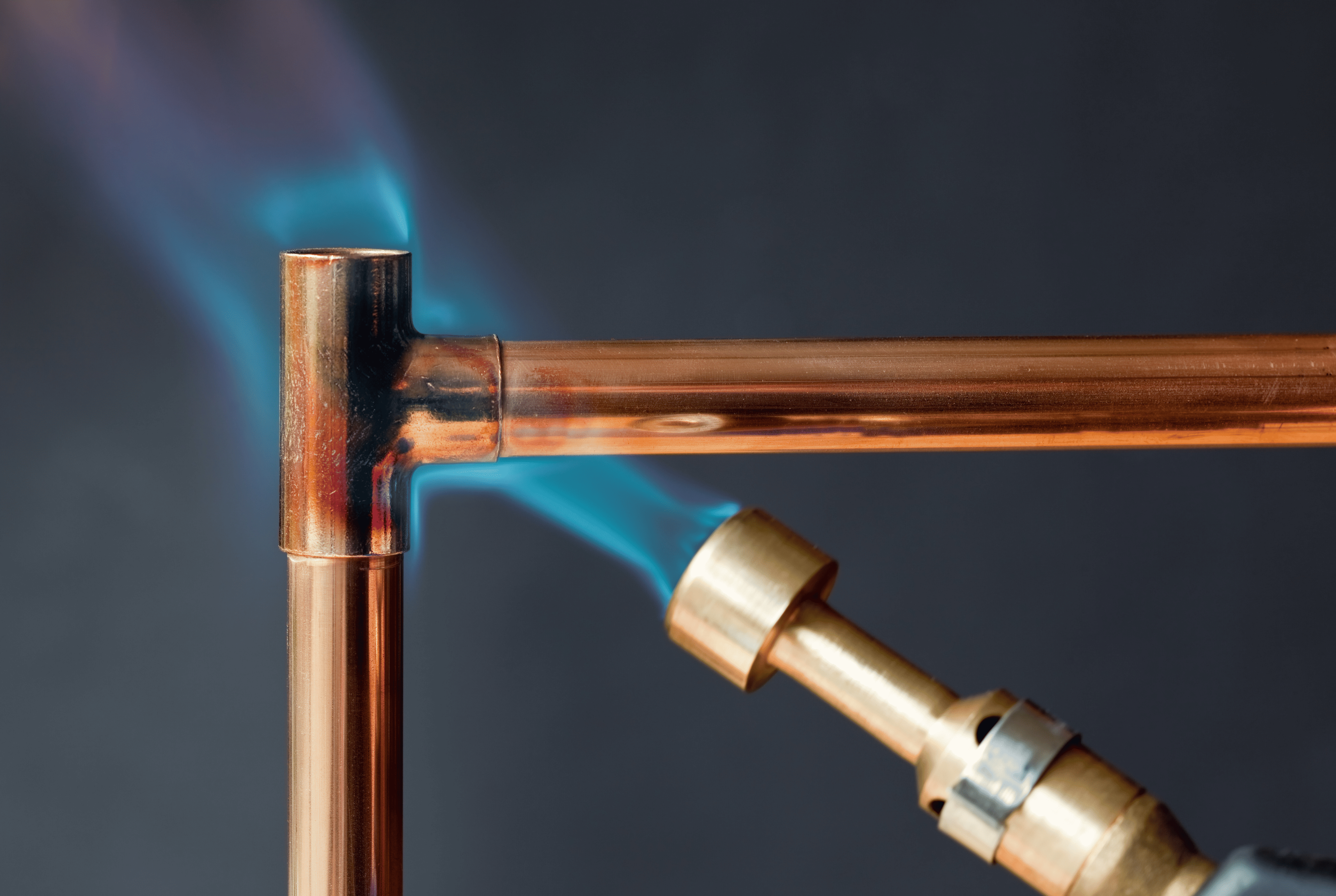

| Internal Surface |

Glossy, pertectly clean conforming ASTM B-280 and EN12735-1

legislation |

||||||

| Heat Conduction at 20°C |

364W/mK | ||||||

| Condition |

Sealed ends, dehumified |

||||||